MINIGRAF Program Memory

- Description

Description

Technical data

Minigraf MP (Memory Program) is a very fast unit designed for manufacturing of average and large-size wooden and MDF frameworks.

Minigraf MP is installed in a PC capable of memorizing up to 3 thousands of connection programmes.

Workpieces are pinned once for all angle joining operation. Settings and tests are performed using PC. Staple driving locations, staple number in a given spot (point), staple driving sequence and the speed of unit performance adjusted to wood hardness can be set for a corresponding (available) workpiece profile.

Additionally, the controller may be connected for operations on barcode scanning device.

Having aligned the workpieces and marked their pinning areas, operator selects from the PC menu an appropriate programme and having once pushed the electric pedal turns on the connection cycle.

Minigraf MP MC (Memory Program MultiChannel) is the most efficient unit intended for mass production of different frame models.

Minigraf MP version features five staple magazines from which, during the turning on process, the staples are dispensed. This allows using different height staples during one operation cycle.

Connection angles: 90 , 120 or 135 degrees

Frame workpiece thickness: 5-80 mm

Frame workpiece width: 10-100 mm

Max. space between joints: 120 mm

Programmed one (out of five types) staple type driving in a given spot (point)

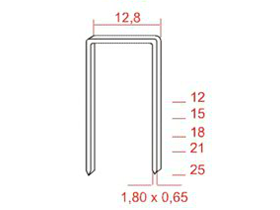

Magazine: 5x 220 vnt. V-shape staples

V staple tips [mm]: 7, 10, 15 mm